Food Grade Grease

BECHEM’s comprehensive range of high performance food grade grease comply to NSF guidelines and are recommended for a wide array of demanding applications. The ingredients comply to the requirements of Food and Drug Administration and is independently verified by NSF.

Additionally, BECHEM’s food grade range of lubricants are also ISO 21469 certified.

Modern day food manufacturing involves complex machines and innovative technologies. With increased awareness on healthy diet, focus has been to produce food whilst retaining nutrition and quality consistently. The sophisticated machines used in the process need to be lubricated regularly to ensure their seamless operation. Although these machines are designed to have zero contact of lubricant with food items in process, possibility of contamination in PPM measure cannot be ruled out during the regular day to day operation. Hence the type of lubricant used is critical.

Typical challenges of food grade lubrication in the food and beverage Industry are:

Food grade grease need to withstand high temperatures as well as contend entry of flour dust/salt etc.

Processed food materials are either acidic or alkaline, lubricants need to be inert and should not affect their performance

Food grade lubricants should be able to meet the requirements of high speed machinery in food processing and packaging

As there is possibility of lubricant getting in direct contact with the food being processed, lubricants need to physiologically harmless, odourless, tasteless and colourless

Long term lubrication desired to ensure maximum productivity

BECHEM’s range of food grade greases

Additionally BECHEM’s food grade grease range are also Kosher and Halal certified to meet the customary and dietary regulations of various regions and cultures.

Synthetic high performance grease with high load carrying ability and superior wear and corrosion protection for food and pharma industry. Berulub FG H 2 EP has good adhesive and sealing properties and provides stiff resistance to hot, cold water, steam, alkalic and acidic solutions, disinfectants and cleaning agents. Berulub FG H 2 EP has good oxidation stability and ageing resistance. Berulub FG H 2 EP is NSF H1 approved as well as Halal and Kosher certified.

Applications: Recommended for buhler pesa mill bearings, plain and roller bearings, cam discs, linear drives, small gears, guides and rollers in food and pharma industry including dairy, breweries, canning factories etc. Berulub FG H 2 EP can be used in central lubrication systems as well.

| Berulub FG-H 2 EP |

|

|---|---|

| Thickener | Special calcium complex soap |

| Base Oil | Synthetic hydrocarbon |

| Temp Range °C | – 40 to + 160 |

Berulub FA 46 is a new generation multipurpose food grade grease with reliable wear and corrosion protection. This special grease has good adhesive and sealing properties and provides stiff resistance to hot, cold water and vapour as well. NSF H1 approved food grade grease, the product is neutral in smell and taste. Berulub FA 46 has good oxidation stability and ageing resistance as well. Solid lubricants within Berulub FA 46 ensures good load carrying capability.

Applications: Recommended for plain, roller bearings and UCP bearings in conveyors, machine parts, guides, in food and pharma sectors such as dairy, edible chip processing, breweries and bottling plants, pulp processing industry etc.

| Berulub FA 46 |

|

|---|---|

| Thickener | Aluminium complex |

| Base Oil | White oil |

| Temp Range °C | -20 to +120 |

High performance synthetic lubricant with anti wear and corrosion protection properties. Advanced additives provide resistance to hot, cold water and vapour as well. The NSF H1 approved food grade grease is neutral in smell and taste.

Applications: Recommended for plain and roller bearings, cam discs, guides and rollers in food and pharma industry including dairy, breweries, bottling plants, canning factories, coffee roasters, potato peelers etc. Can be used in central lubrication systems.

| Berulub FB 34 |

|

|---|---|

| Thickener | Aluminium complex soap |

| Base Oil | Polyalphaolefin |

| Temp Range °C | -40 to +160 |

Synthetic high performance grease with superior wear and corrosion protection for food and pharma processing industry. Berulub FG H 2 SL has good adhesive and sealing properties and provides stiff resistance to hot, cold water, steam, alkalic and acidic solutions, disinfectants and cleaning agents. FG H 2 SL ensures high strength lubricating film between contact partners even under high loads as well as prevents sticks slip phenomenon. This special grease is NSF H1 approved as well as Kosher and Halal certified. Berulub FG-H 2 SL can be used in central lubrication systems.

Applications: Recommended for plain and roller bearings, cam discs, linear drives, small gears, guides and rollers. Recommended for applications such as potato peeler, decanter in food and pharma industry including dairy, breweries, canning factories, coffee roasters, pellet mill etc. Also suitable for paper processing machines.

| Berulub FG-H 2 SL |

|

|---|---|

| Thickener | Special calcium complex soap |

| Base Oil | Synthetic hydrocarbon |

| Temp Range °C | -45 to +160 Short term +200 |

Special paste for heavily loaded screws and plug time connections exposed to extreme high temperatures. Berulub 932 Antiseize Paste provides wear and corrosion protection. Resistant to hot and cold water and acidic media. Possesses good oxidation stability. Berulub 932 Antiseize Paste is NSF H1 approved.

Applications: Prevents cold welding, fretting corrosion as well as seizure of screws, nuts in spindles, press fits exposed to high temperatures. Suitable for applications in variety of industries including food, beverage and packing, mining, ship building, steel, cement and chemical processing

| Berulub 932 Antiseize Paste |

|

|---|---|

| Thickener | Gel |

| Base Oil | Medical white oil |

| Temp Range °C | – 40 to + 1400 |

Synthetic high temperature grease for extended lubrication life. The special product with advanced formulation has good oxidation stability as well as high thermal and chemical stability. Berutox VPT 54 is neutral in smell and has excellent compatibility with plastics and elastomer even when in vacuum or when expose to radiation and chemicals. Berutox VPT 54 is NSF H1 approved as well as Kosher and Halal certified.

Applications: Recommended for plain and roller bearings exposed to high temperatures in electric motors, hot air fans, conveyor systems, baking equipment, tyre mould etc. As a life lubricant, VPT 54 is recommended to prevent noise caused from vibrations both inside/outside the vehicle and for high temperature applications in food and pharma industry.

| Berutox VPT 54 |

|

|---|---|

| Thickener | PTFE |

| Base Oil | Perfluoropolyether |

| Temp Range °C | – 30 to + 230 |

The fully synthetic PFPE/PTFE product is a superior high temperature grease with extended life lubricating characteristics. Berutemp 500 T2 is highly resistant to thermal and chemical decomposition. 500 T2 is compatible with plastic and elastomer materials. Berutemp 500 T2 is NSF H1 approved as well as Kosher and Halal certified.

Applications: Berutemp 500 T2 is recommended for high temperature applications in food and pharma processing industries as well. Some examples are friction elements in wafer biscuit production machines, turning rollers in automotive paint shops, corrugator roll, blister packaging, latex curing oven, segment moulds in tyre industry etc.

| Product | Thickener | Base Oil | Temp Range °C |

|---|---|---|---|

| Berutemp 500 T2 | PTFE | Perfluoropolyether | – 20 to + 260 |

Synthetic grease with PTFE additives for life lubrication of applications in food, pharma and sanitary fitting industry. Berulub Sihaf has good compatibility with plastic and elastomer material. The food grade grease is NSF H1 approved as well as Halal and Kosher certified.

Applications: Recommended for air and rotary distributors of high performance filling machines in the brewery and beverage industry. Does not impact forth formation in relevance to beverage industry. Also suitable for ceramic sealing, water faucet, control discs in single lever mixing valves, lubrication and sealing of plug valve, rubber sleeves in sanitary ware and fitting applications. Berulub Sihaf 2 is approved and registered under German (UBA, DVGW), British (WRAS), French (ACS), Austrian (TGM VA-KU 2337), Belgium (Belgaqua) standards for drinking water

| Berulub Sihaf – Available in NLGI 1 and 3 |

|

|---|---|

| Thickener | PTFE |

| Base Oil | Silicon oil |

| Temp Range °C | – 40 to + 160 |

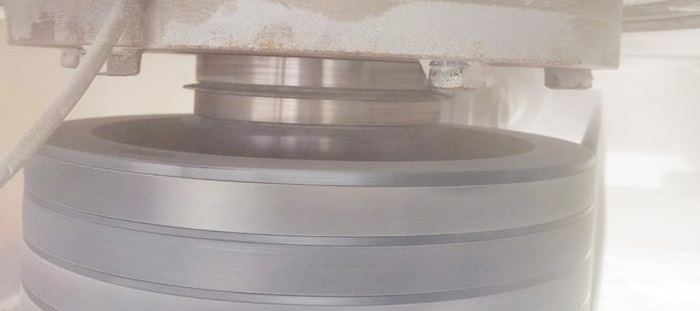

Universal long life EP grease with excellent water resistance for food processing industry. Berulub WP 402 H1 has excellent consistency temperature behaviour as well as anti wear properties. The special complex soap grease offers good adhesion and reliable corrosion protection as well. The NSF H1 approved product is neutral in smell and taste.

Applications: Recommended for roller and plain bearings, joints and guides, pellet presses of food processing industries, machines and applications in food processing segments exposed to high as well as shock loads.

| Berulub WP 402 H1 |

|

|---|---|

| Thickener | Aluminium Complex |

| Base Oil | Silicon oil |

| Temp Range °C | – 20 to + 150 |

Why BECHEM Food Grade Lubricants?

BECHEM’s comprehensive range of high performance food grade grease comply to NSF guidelines and are recommended for a wide array of demanding applications. The ingredients comply to the requirements of Food and Drug Administration and is independently verified by NSF.

BECHEM’s food grade lubricants have,

High water resistance

Excellent oxidation stability

Low wear rates

Good compatibility and adhesion with construction materials such as metal and plastics

NSF’s classification of lubricants

The evaluation programme for non-food compounds adopted by the National Sanitation Foundation (NSF) is the most widely industry accepted norm across the world to assess suitability of the items including lubricants used in the food manufacturing process.

- H1 Lubricants – Lubricants that could have incidental food contact during processing

- H2 Lubricants – Lubricants with no possibility of food contact, however still used in machinery involved in food processing.

- H3 Soluble Oils – Lubricants that can have direct contact with edible food

For more details on NSF’s regulation and scope, visit http://www.nsf.org

Latest Blog Updates

Enhancing operational reliability of Vertical shaft impactor (VSI) crushers with effective lubrication

Vertical shaft impactor (VSI) crushers, widely used in the construction and mining industries, are uniquely designed for high-impact crushing. The crushers are suitable for a wide range of applications including…

Challenges in lubrication of bearings exposed to high temperatures.

Case study on impact of high temperatures and loads on lubrication and therefore life of plummer block bearings in the drying range of a textile spinning mill. The drying range…

How effective lubrication of conveyor chain can impact process efficiency even at high temperatures?

Chains in drives and conveyors are highly stressed components in production lines as they typically endure harsh operating conditions like high temperatures, high load, dusty environments etc. High friction is…

Improving operational reliability of auger with synthetic food grade grease

Food and pharma processing industries adhere to a highly systematized process workflow having strict hygiene standards and food safety regulations. Methodical cleaning and regular sanitization of equipments are part of…

Support response: Median email response time of less than 3 hours.