Consistent Performance with Staroil KNT 32

June 7, 2022

Upto 24% reduction in oil consumption with BECHEM Staroil KNT 22

June 7, 2022BECHEM Staroil KNT: High Performance Knitting oil for Longer Needle Life

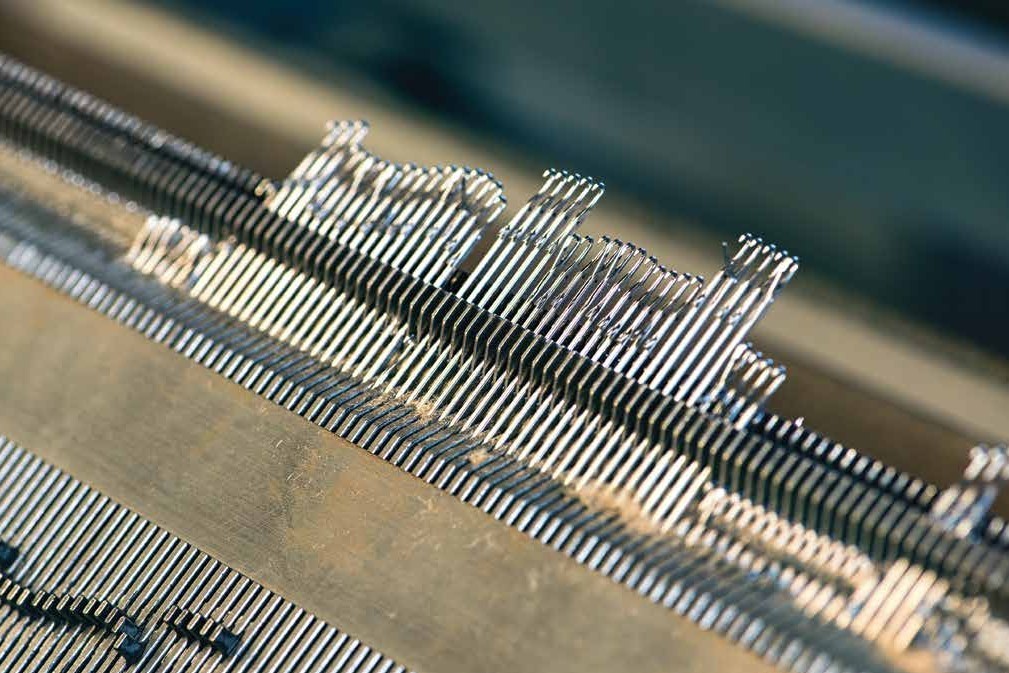

BECHEM Staroil KNT range of knitting oils are developed on ultra-refined base oils and performance additives which ensure high lubricity and low frictional coefficients between the frictional partners of sinker and needle.

The special anti-wear additive package within Staroil KNT 22 and 32 helps in reducing severe friction and wear during the emergency run conditions of the knitting machine such as start-up and shutdown phase. The best-in-class lubrication performance of BECHEM Staroil KNT reduces friction, wear and unnecessary temperature rise, thereby increasing the productive life of needle and sinkers. Additionally, the Staroil KNT range of knitting oils have lower volatile losses thereby ensuring lower oil consumption per machine per day.

GOTS Approved

The knitting oil range of BECHEM Staroil KNT 32 and 22 are GOTS approved (Global Organic Textile Standard) as knitting oil inputs for application in the processing of GOTS certified textile products.

BECHEM Staroil KNT range of knitting oils Case study

Support response: Median email response time of less than 3 hours.