Support for a cause of medical emergency

February 16, 2021

Effect of drawing oil on production efficiency in bright bar drawing process

November 25, 2021Can lubricants help reduce excess energy consumption in ‘Ring-frame machines?

Energy consumption in ring frame machines

Optimum utilisation of energy is one of the key parameters in reduction of production costs in an industrial set-up.

Considering the cost of fuels and the aspect of high energy consumption in textile industry, many studies and activities have been conducted with focus on energy conservation during spinning and weaving processes.

A dipstick survey by the BECHEM team on ‘power consumption in spinning processes’ with sample comprising of prominent mills, estimated that power charges contributes roughly about 15 to 20% of the total cost to produce one kilogram of yarn. Further the study reveal that, the ‘Ring Frame’ department contributes approximately about 45 to 50% of the power cost in a spinning mill. The rest distributed among the processes of ‘carding’, humidification plant, autoconer, and compressor sections.

A key factor that most mill owners agreed to was that about 85% of the power in a ring frame machine was used in driving the spindles. Based on the findings of the dipstick study, the BECHEM team worked with Maintenance teams of some mill owners to investigate the possibility of reducing power consumption with effective lubrication in key applications of the ring frame machine.

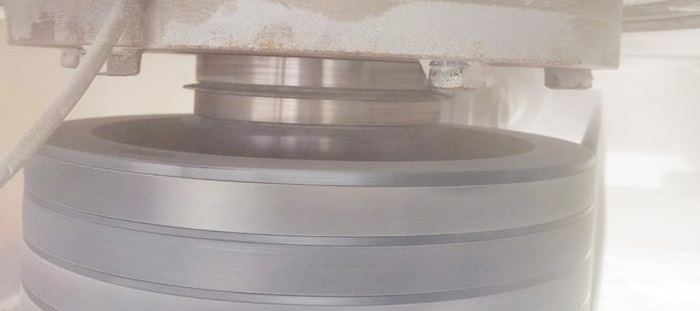

Application 1: Ring frame jockey pulley, understanding the cause for spike

The study unravelled a concern expressed by a few mill owners of the sudden spike in power consumption after the scheduled re-greasing (6 months) of the ‘ring frame jockey pulley bearings’. Accordingly, the BECHEM team joined efforts with the maintenance team of one of the mills with a capacity of 36,000 spindles to understand the root cause for the sudden spike.

kW: Kilowatt

| Count | 80 |

| TPI(Twists per inch) | 45.6 |

| Motor kW | 55 |

| Bearing Type | Ball bearing (Non-standard) – Precision bearing |

| No. of jockey pulleys/frame | 600 (for 1200 spindles R/F) |

| Speed | between 6,000 to 7,500 rpm (depending on spindle speed) |

| Operating temperature | 45°C |

| Current grease | Conventional AP 2 grease |

| Lubrication frequency | 6 months |

| Day | Doff no. | Total kW-h | Avg. spindle speed in RPM | Total yarn production (kg.) | Unit per kg. (UKG) |

| 1 | 1 | 122.995 | 19726 | 38.75 | 3.17 |

| 1 | 2 | 124.329 | 19714 | 39.05 | 3.18 |

| 1 | 3 | 123.550 | 19768 | 38.65 | 3.20 |

| 2 | 4 | 123.708 | 19617 | 38.50 | 3.21 |

| 2 | 5 | 123.331 | 19658 | 38.10 | 3.24 |

| 3 | 6 | 123.245 | 19677 | 38.60 | 3.19 |

| 3 | 7 | 125.902 | 19555 | 39.35 | 3.20 |

| 3 | 8 | 125.029 | 19594 | 38.70 | 3.23 |

| 3 | 9 | 124.166 | 19635 | 38.40 | 3.23 |

| 3 | 10 | 122.335 | 19625 | 38.25 | 3.20 |

| Avg. consumption of power per Kg. of yarn | 3.21 | ||||

| Day | Doff no. | Total kW-h | Avg. spindle speed in RPM | Total yarn production (kg.) | Unit per kg. (UKG) |

| 1 | 1 | 154.799 | 19507 | 38.75 | 3.99 |

| 1 | 2 | 153.357 | 19923 | 37.80 | 4.06 |

| 1 | 3 | 151.560 | 19739 | 37.60 | 4.03 |

| 2 | 4 | 149.228 | 19644 | 38.35 | 3.89 |

| 2 | 5 | 141.000 | 19756 | 38.00 | 3.71 |

| 3 | 6 | 141.194 | 19696 | 38.05 | 3.71 |

| 3 | 7 | 137.235 | 19553 | 37.45 | 3.66 |

| 3 | 8 | 136.280 | 19449 | 36.90 | 3.69 |

| 4 | 9 | 135.798 | 19768 | 38.20 | 3.55 |

| 4 | 10 | 134.840 | 19739 | 38.35 | 3.52 |

| 4 | 11 | 133.801 | 19916 | 37.30 | 3.59 |

| 4 | 12 | 134.818 | 19538 | 38.65 | 3.49 |

| 4 | 13 | 134.587 | 19842 | 38.30 | 3.51 |

| 5 | 14 | 132.565 | 19739 | 37.70 | 3.52 |

| 5 | 15 | 132.369 | 19736 | 37.85 | 3.50 |

| 5 | 16 | 131.048 | 19883 | 37.80 | 3.47 |

| 5 | 17 | 130.412 | 19506 | 38.05 | 3.43 |

| 5 | 18 | 129.371 | 19830 | 38.40 | 3.37 |

| Avg. consumption of power per Kg. of yarn | 3.65 | ||||

Avg. consumption of power per kg of yarn before re-greasing of bearings with conventional AP 2 grease: 3.21 UKG (units per Kg.)

Avg. consumption of power per kg of yarn after re-greasing of bearings with conventional AP 2 grease: 3.65 UKG (units per Kg.)

Increase in power consumption by 13.7% after re-greasing of bearings with conventional AP 2 grease

The unit with 36,000 spindles had 30 ring frame machines functioning at full capacity. Extrapolating the increase in power consumption for all the 30 ring frame machines in the section and also considering the re-lubrication exercise twice in a year, the excess units consumed was substantial.

| Description | Consumption in Units |

| Power consumed per day at the ‘Ring Frame’ section | 30,000 units |

| Power consumed per day at the ‘Ring Frame’ section with 4% increase | 31, 200 units |

| Difference in power consumption per day | 1,200 units |

| Increase in power consumption, considering the trend sustains for 15 days | 18,000 units |

| Assuming a re-lubrication frequency for the ‘jockey pulley bearing’ as 6 months, increase in annual power consumption | 36, 000 units |

Root cause analysis

Observing that the trend of rise in power consumption lasted about 15 days after the re-greasing exercise, the BECHEM team arrived at the possible causes,

- Internal friction caused by the ‘conventional AP 2 grease’ (with high base oil viscosity) within the bearing was the most possible reason for power increase in the application

- The ‘Maintenance team’ practiced the thought, ‘one grease for all applications in the ring frame’

- The existing ‘convention AP 2 grease’ with a base oil viscosity of 130 cSt was at least 8 times more than the application requirement

- Actual application requirement was for a special grease with base oil viscosity of 15 to 20 cSt

| Bearing Type | Ball bearing (Non-standard) – Precision bearing |

| No. of jockey pulleys/frame | 600 (for 1200 spindles R/F) |

| Speed | between 6,000 to 7,500 rpm (depending on spindle speed) |

| Operating temperature | 45°C |

BECHEM’s Recommendation: Berulub KR EP Tex 2

The BECHEM team recommended to replace with existing ‘conventional AP 2’ grease with ‘Berulub KR EP Tex 2’ for the application.

Berulub KR EP Tex 2 is a high-speed bearing grease developed on low viscous, synthetic base oil combination for consistent long-term lubrication. The special grease is proven for miniature or precision bearings as it offers low internal friction. Additionally, ‘Berulub KR EP Tex 2’ protects mechanisms from corrosion and humidity.

Trial with Berulub KR EP Tex 2

- A spare set of jockey pulleys for one ‘ring frame’ (600 nos.) was greased with the recommended quantity of Berulub KR EP Tex 2 and mounted

- Energy meter was coupled with the ring frame and readings were recorded for every doff

Application details: Ring frame machine No. 43

Count: 80s

TPI (Twists per inch): 45.6

Motor kW: 55

| Bearing Type | Ball bearing (Non-standard) – Precision bearing |

| Quantity of grease required per jockey pulley bearing | 1.3 g |

| No. of jockey pulleys/frame | 600 (for 1200 spindles R/F) |

| Total grease quantity required per ring frame | 800 g approx. |

| Speed | between 6,000 to 7,500 rpm (depending on spindle speed) |

| Operating temperature | 45°C |

Readings after re-lubrication with Berulub KR EP Tex 2

| Day | Doff no. | Total kW-h | Avg. spindle speed in RPM | Total yarn production (kg.) | Unit per kg. (UKG) |

| 1 | 1 | 126.063 | 19654 | 38.85 | 3.24 |

| 1 | 2 | 124.578 | 19714 | 38.25 | 3.26 |

| 2 | 3 | 125.283 | 19792 | 38.30 | 3.27 |

| 2 | 4 | 127.374 | 19595 | 39.65 | 3.21 |

| 2 | 5 | 125.281 | 19720 | 39.00 | 3.21 |

| 3 | 6 | 125.022 | 19757 | 39.00 | 3.21 |

| 4 | 7 | 124.485 | 19666 | 38.95 | 3.20 |

| 4 | 8 | 124.756 | 19624 | 38.25 | 3.26 |

| 4 | 9 | 125.222 | 19817 | 38.25 | 3.27 |

| 5 | 10 | 125.115 | 19489 | 38.70 | 3.23 |

| Avg. consumption of power per Kg. per yarn | 3.24 | ||||

Observations

- Initial results indicated no increase in power consumption after the ‘re-greasing’ exercise

- Interim check of the grease quality after 6 months indicated no deterioration in quality of the grease

- Re-greasing frequency was extended’ for another 6 months, with a minimum life of 1 year and beyond

Benefits to the customer

1. No increase in power consumption, translating to lower production costs

- Potential annual saving of Rs.2 lakhs at the ring frame section (with capacity of 36,000 spindles) that would have otherwise been the cost to customer due to the surge in power consumption after re-lubrication exercise

2. Increase in re-lubrication frequency to 12 months and beyond helped in,

- Better utilisation of man power

- Increase in productivity with reduction in machine idle time

While the word spread on the reduction of power consumption in ‘ring frame machine’ with the special grease, more Mill Owners opened up for the trial orders of Berulub KR EP Tex 2.

The Berulub KR EP Tex 2 is also recommended for draw frame end bush bearing, TFO pot bearing, and OE spinning rotor bearing.

Disclaimer: Results could vary depending on the machine condition, mill operating parameters and environment and maintenance practices. The information provided is intended to be used as a guide and does not necessarily represent a specification or provide an exact result. It is advised for Customers to carry out trials in Consultation with BECHEM’s Application Engineering team for further validation. For any further clarifications, please write to us at [email protected] or leave a query.