A case study on dirty bins affecting rejection rates at a leading auto component manufacturer

The production team at an auto component manufacturing company had trouble cleaning its component bins, impacting both component and shop floor cleanliness. Having embraced ‘total quality management’, the ISO/IATF certified company was keen to arrive at an effective solution to this niggling issue.

Background

The Auto component manufacturer supplies to top Auto brands with exposure to both segments of passenger and commercial vehicles. Credited as one of the largest manufacturer of steering yokes in India, the company’s product portfolio also includes, connecting rods, automobile housing, gears as well as other precision turned components.

With close to 30 years of experience, and having imbibed the principles of ‘total quality management system’ the company had mastered complexities in manufacturing critical automotive parts. Supported by a highly aware and ‘quality conscious’ work force, the company had adopted stringent quality checks and was known for its commitment to fulfil clients’ requirements with precision.

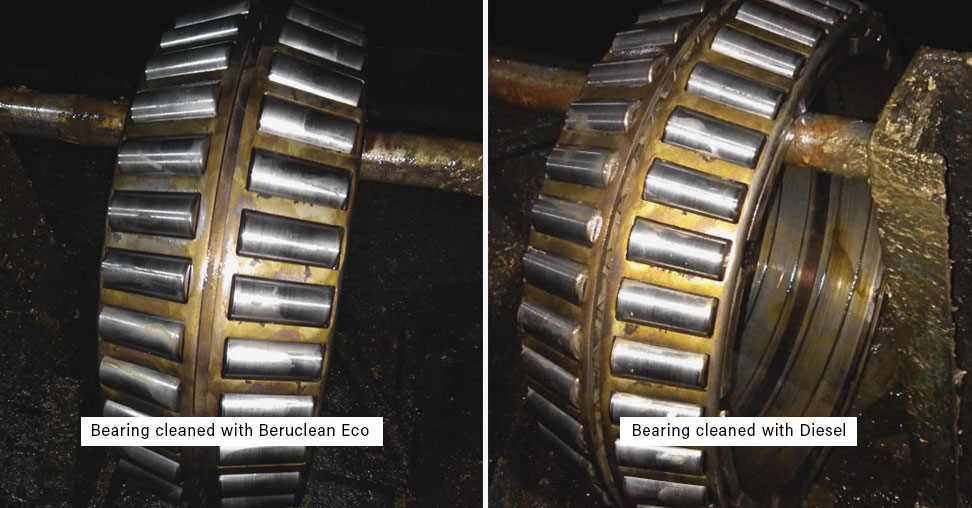

During one of its regular exercises to identify areas for improvement, the Production team at the works noticed unclean bins in use for moving auto parts from one department to another. These bins would often contain grease and oil residues that in turn would attract dust contaminants resulting in dry sludge over time. Dirty bins meant contamination threat for finished components and possible rejection scenario from the Customer.The team realized that the existing cleaning system for bins in place was not effective despite the best efforts. As contaminants remained visible, the team had to establish a secondary manual cleaning process that was unproductive and affected the workflow.

However, unclean bins did not reflect the quality standards employed and posed a potential embarrassing situation for the Production team during Customer visits. Also, unclean bins are a major reason for corrosion of finished components

Part Cleanliness

Finished auto parts are subjected to tests to ensure cleanliness at supplier’s end and also at customer’s end. Millipore test is one of the popular tests to check for impurities. Failure in this test at supplier’s end results in additional cleaning of parts. In case of failure at the customer’s end would result in rejection of the entire batch.

Millipore Test: This test verifies part cleanliness by using gravimetric evaluation and evaluation of particle counts and sizes.

The existing cleaning agent wasn’t sufficient enough to obtain cleaner bins. During a regular prospecting visit, the BECHEM team learnt about the concern of unclean bins from the Production personnel. The BECHEM team understood the criticality of the issue and suggested an inspection of the existing bin cleaning process.

Observation of Existing Setup

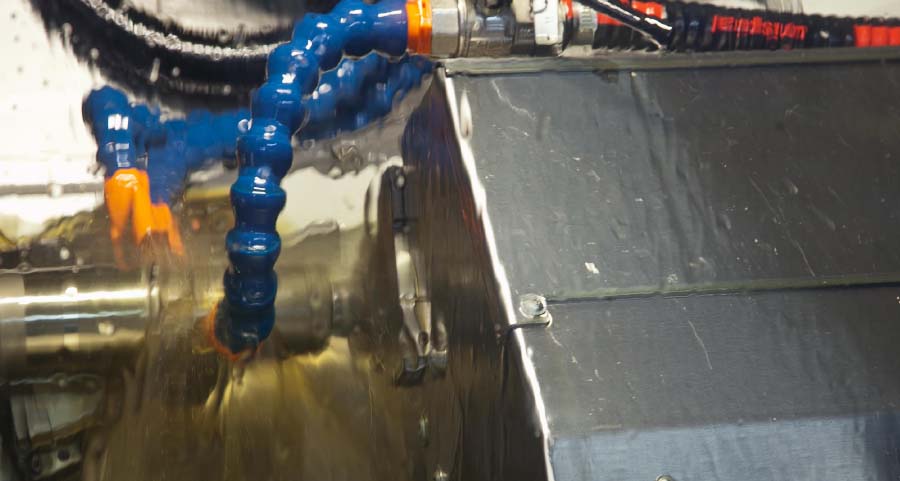

Cleaning machine installed at the works used jet spray to rinse off impurities from plastic bins. The cleaning process utilized DM (de-mineralized) water along with regular washing powder with cycle time of 5 minutes. The setup with tank capacity of 400-liter had in built heater that could maintain the sump temperature up to 60 °C. However, the team observed the lack of filtration system in the existing set up resulting in accumulation of excess sludge at the bottom.

BECHEM’s Approach

Upon examining the process followed, BECHEM suggested few modifications to the existing setup including installation of pre-filtration system, repositioning of heat sensors and increasing the size of exit valves for better drainage of sludge.

Recommendation

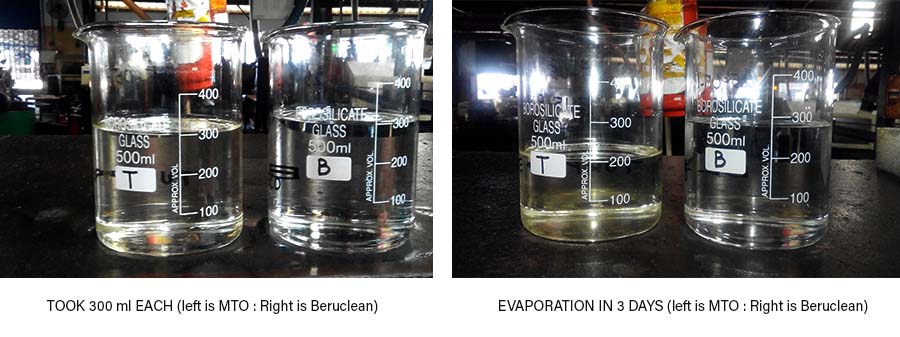

Product recommendation was very critical as the bin cleaning system utilized jet spray and hot water for cleaning. A typical solvent based cleaner with low flash point could cause a potential fire incident during the process. A water based cleaner with good wetting and soaking properties was vital.

BECHEM recommended Beruclean 113 EMF, a universal water-soluble alkaline cleaning agent with low foaming properties. Equipped with special wetting additives, the high performance industrial cleaner is suitable for Aluminium, Cast Iron, Steel and non-ferrous metals as well. Although alkaline in nature, Beruclean 113 EMF is compatible with the piping or flanges from copper alloys used in cleaning systems. Also, Beruclean 113 EMF is highly recommended for spray jet cleaning.