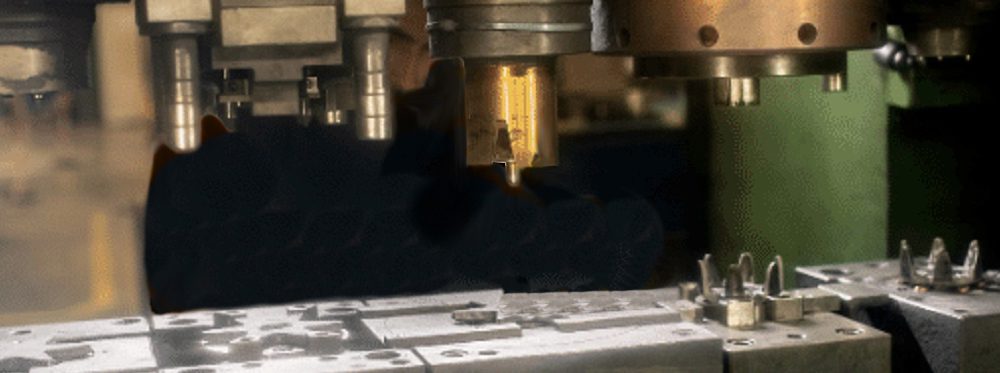

High Performance Mist Lubricant For Increased Tool Life

February 11, 2020

Plastic Lubricants from BECHEM

March 11, 2020Electrical Switch Lubricants from BECHEM

Dark night. Pouring rain. And a wiper that won’t start. Blame the lubricant.

Driving during a heavy downpour without being able to regulate the wiper can be a hazard. The wiper is one of the many applications where the electrical switch plays a crucial role as a control device. From the window regulator to the critical ignition start mechanism, modern day cars possess numerous mechatronic components that are controlled and regulated by switches. Switches internally contain fixed and movable surfaces made up of copper, silver, gold and tin plated metals for regulating the flow of current. Contacting surfaces means friction, resulting in heat generation and surface wear. Over a period of time, this would finally lead to failure of then switch itself.

Performance lubricants

Contacting surfaces in switches are either finger sliding or button type. Automotive switches carry current from the order of a few milliamps to 60 Amps and beyond depending on the intended use of the switch. Housing of these contacts is made of special engineering plastics which are sensitive to lubricants. The electrical contact in the switch has to be protected against corrosion, silver sulphurisation and sliding wear. Most importantly, it should be noiseless and provide a smooth operating experience to the user. The need is for a special lubricant that can withstand the flow of current and harsh operating conditions inside a switch with minimum presence for a very long time.

Lubrication requirement of automotive switches

Automotive switches need to operate in diverse environmental conditions. Be it burning hot terrain or cold freezing atmosphere, the switch needs to function seamlessly. Correspondingly, the lubricant too needs to have a wide operating temperature range . Since intermittent re-lubrication of automotive switches is impossible, the lubricant needs to maintain its composition until the lifetime of the auto component. With an ability to form a thin and an everlasting strong lubrication film which helps in increasing the area of contact, BECHEM contact lubricants improve efficiency of the system.

Heat generation

Electric arc formation in switches is a common phenomenon that generates heat and thermally decomposes contacting surfaces. Ionization of surrounding air and rise in temperature between contacting surfaces causes metal transfer resulting in the formation of new ‘peaks and troughs’. Lubricated surfaces generally restrict arc formation. However, lubricants unable to withstand high temperatures oxidize gradually leaving dry powdery residues. This results in increased contact resistance and further increase in temperature.

Voltage drop due to wear

An outcome of the sustained wear and degradation of the plated contacting surfaces is drop in voltage. Performance of the lubricant has a direct impact on the voltage drop and consequently on performance of the automotive component.

BECHEM Lubricants

BECHEM’s lubricants for electrical and mechatronic components are silicon free and have the ability to perform within wide operating temperature range (-40 C to +140 C). These intelligent lubricants, formulated with special low viscosity synthetic oil and organic polymer thickeners, protect contacting surfaces by providing excellent compatibility with engineering plastics and also possess excellent noise dampening properties.

BECHEM’s Expertise

BECHEM’s lubricants for switches are tested exhaustively for over 50,000 cycles (On/off cycle) equivalent to 7 to 10 years of life of the switch under various simulated driving conditions. Working closely with top auto and component manufactures, BECHEM has developed intelligent lubricants that suit their applications and systems. When you need your electrical switches to work unfailingly, trust the international leader.