High Temperature Greases

BECHEM’s range for high temperature applications include greases developed from special Polyurea to advanced PTFE thickeners blended with synthetic as well as special mineral base oils.

Conventional greases are not designed to withstand high operating temperatures. At high temperatures, grease oxidation rate is rapid. Due to the presence of thermal energy, significant increase in oil separation and oil evaporation rates are observed. The deterioration rate is higher for greases with base oils that have low viscosity index. Breakdown of the grease structure and lubricating film would lead to seizure of contact partners and failure of the application.

BECHEM’s range for high temperature applications include greases developed from special Polyurea to advanced PTFE thickeners blended with synthetic as well as special mineral base oils. These high temperature greases possess excellent temperature to consistency behaviour. The advanced additive package consisting of anti oxidants and solid lubricants ensure lubrication at elevated temperatures for longer duration’s, thereby reducing re-lubrication frequency.

BECHEM’s range of high temperature greases

The fully synthetic PFPE/PTFE product is a superior high temperature grease with extended life lubricating characteristics. Berutemp 500 T2 is highly resistant to thermal and chemical decomposition. 500 T2 is compatible with plastic and elastomer materials. Berutemp 500 T2 is NSF H1 approved as well as Kosher and Halal certified.

Applications: Berutemp 500 T2 is recommended for high temperature applications in food and pharma processing industries as well. Some examples are friction elements in wafer biscuit production machines, turning rollers in automotive paint shops, corrugator roll, blister packaging, latex curing oven, segment moulds in tyre industry etc.

Fluorinated grease based on advanced formulation for extreme temperatures and achieved extended re-lubrication intervals. Berutox VPT 64 has excellent thermal and chemical stability as well as good oxidation stability. Berutox VPT 64 is neutral in smell and has excellent compatibility with plastics and elastomer material.

Applications: Recommended for bearings exposed to extreme high temperatures for extended duration. Also recommended for plain and roller bearings in applications such as electric motors, hot air fans, conveyor systems, baking equipment, tyre mould etc. As a life lubricant for automotive components, VPT 64 is recommended to prevent noise caused from vibrations both inside/outside the vehicle. Example: dashboards, seat systems, door modules etc.

| Berutox VPT 64 |

|

|---|---|

| Thickener | PTFE |

| Base Oil | Perfluoropolyether |

| Temp Range °C | -30 to +260 |

Synthetic high temperature grease with low evaporation tendency for long life lubrication. Berutemp 170 provides good resistance to water. Possesses good extreme pressure (EP) and anti wear (AW) properties.

Applications: Recommended for plain and roller bearings exposed to extreme high temperatures such as paint shop overhead conveyor trolley bearings, bearings in wafer biscuit production machines etc.

| Berutemp 170 |

|

|---|---|

| Thickener | PTFE |

| Base Oil | Synthetic |

| Temp Range °C | -20 to +200 |

Fully synthetic grease for long life lubrication with excellent consistency-temperature behaviour. This high temperature grease also provides excellent resistance to water, chemical and steam ingress. Protects bearings from corrosion.

Applications: Berutox FH 28 KN is recommended for bearings and applications subjected to high temperatures such as drying kilns, conveyor systems, paint shop trolley wheels, hot air fans, annealing furnaces, electric motors etc. Suitable for lubrication of pulp press bearings in paper plants.

| Berutox FH 28 KN |

|

|---|---|

| Thickener | Polyurea |

| Base Oil | Polyalphaolefin |

| Temp Range °C | -30 to +180 / +200 short term |

Fully synthetic high temperature grease for long life lubrication of bearings exposed to elevated temperatures and high loads. This high performance grease has excellent consistency-temperature behaviour. Does not form residues at high temperatures. Berutox FH 28 EPK II has good sealing properties against water and corrosive media. Provides protection against corrosion and wear .

Applications: Berutox FH 28 EPK II is recommended for bearings and applications exposed to high temperatures and loads in cooling beds, rotary kilns, conveyor systems, annealing and drying furnaces, electric motors, hot air fans, gate valves in bulk material container systems etc.

| Berutox FH 28 EPK II |

|

|---|---|

| Thickener | Polyurea |

| Base Oil | Polyalphaolefin |

| Temp Range °C | -30 to +180 |

Synthetic high performance grease with high speed index for high speed applications and spindle bearings. Berutox FB 22 provides long term lubrication even under extreme temperatures and operating conditions. Synthetic PAO base oil in FB 22 ensures extended service life. Smooth structure of FB 22 ensures minimal internal friction translating to reduced start-up torque and therefore less temperature build up. FB 22 provides superior corrosion protection as well as excellent resistance to alkaline coolant attacks. Extreme pressure additives offer good lubrication under medium to high loads and vibrations.

Applications: Recommended for lubricated for life bearings that demand fully synthetic base oil grease. FB 22 is compatible with commonly used sealing and cage materials. Recommended for high speed spindle bearings Example : In machine tools, threaded spindles, toothed gear in small gears, worm gear etc.

| Berutox FB 22 |

|

|---|---|

| Thickener | Barium Complex |

| Base Oil | Polyalphaolefin |

| Temp Range °C | -30 to +180 |

High temperature multipurpose grease for long term lubrication. Beruplex HTA is free from solid lubricants and is apt for use in central lubrication systems.

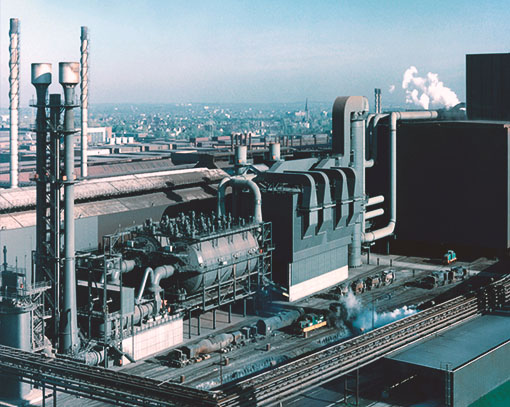

Applications: This high performance grease is recommended for lubrication of bearings of electric motor, hot air fans, conveyor systems exposed to severe radiation heat, furnaces, converters, pouring ladles, clutch thrust bearing etc. Also recommended for lubrication of bearing guide rollers of continuous caster, hot slab transportation systems in metallurgical plants, circular oscillating sieves, tar mixer etc.

| Beruplex HTA |

|

|---|---|

| Thickener | Aluminium Complex |

| Base Oil | Mineral Oil |

| Temp Range °C | -25 to +190 |

High temperature grease for long term lubrication, possessing excellent temperature consistency. This heavy duty grease has excellent pumpability for centralised systems. Provides good corrosion protection.

Applications: Berutox M21 KN is recommended for bearings and applications exposed to high temperatures and loads in continuous caster segments, cooling beds, conveyor systems, annealing and drying furnaces etc.

| Berutox M21 KN |

|

|---|---|

| Thickener | Polyurea |

| Base Oil | Mineral Oil |

| Temp Range °C | -20 to +180 |

High performance multipurpose EP grease for long life lubrication. Berutox M21 EPK has excellent sealing qualities with superior resistance to water and steam. Provides excellent corrosion and wear protection.

Applications: Recommended for dryer section bearings and hot air fans in paper plants, precision bearings such as top arm bearings and variator systems of spinning machines in textile industry. Suitable for lubrication of friction partners in door locking systems, hinged joints, wheel hub bearings, shifting linkages and bearings in water pumps of automotive industry. Also recommended for rotor shell bearings of pellet presses.

| Berutox M21 EPK |

|

|---|---|

| Thickener | Polyurea |

| Base Oil | Mineral Oil |

| Temp Range °C | -20 to +160 |

Ceritol PSA 12 H has good pumping properties in the context of centralised lubrication systems exposed to thermal radiation. PSA 12 H possess good corrosion protection properties and provides good resistance to regular as well as aggressive water.

Applications: High temperature grease Ceritol PSA 12 H is recommended for plain and roller bearings exposed to thermal loads, bearings of dryer section and hot air fans in paper processing industry, guide rollers in slab and billet casters.

| BECHEM Ceritol PSA 12 H |

|

|---|---|

| Thickener | Special Polyurea |

| Base Oil | Mineral Oil |

| Temp Range °C | -20 to +160 |

Connect with us for more information on product samples, technical comparisons and details on pack sizes.

Latest Blog Updates

Support response: Median email response time of less than 3 hours.