Effective lubrication of pellet feed mill bearings

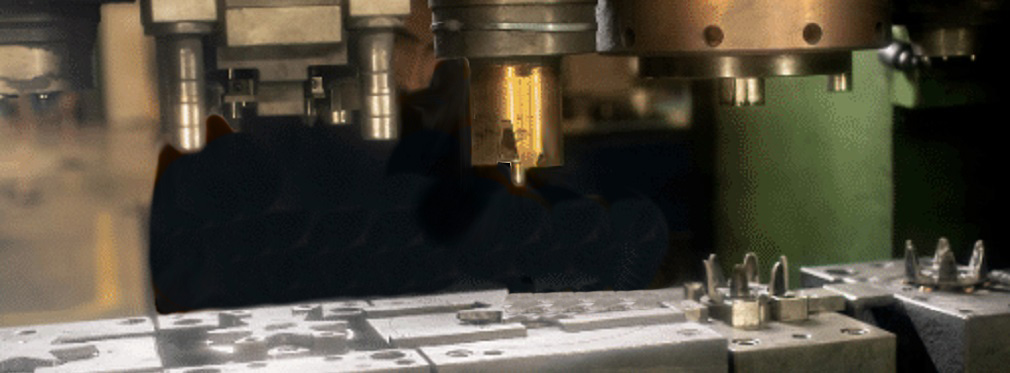

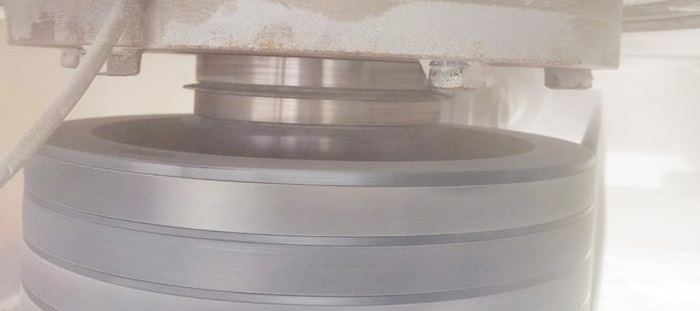

While the straight up grease cost is an important consideration, maintenance engineers recognize the importance of high quality lubricants and correct lubrication practices for effective plant maintenance and a reliable…